Exploring the Holistic Impact of Clean Energy-Powered Cold Chain

Addressing post-harvest loss (PHL) with cold chain technology unlocks significant economic gain for smallholder farmers across emerging markets, improves product quality and makes a meaningful impact on climate adaptation and mitigation, writes Tanya Kothari, Agriculture Research Manager at Shell Foundation (SF)

The Voices in AgTech blog series highlights the people and organisations whose work has helped increase awareness of solar-powered agricultural technologies. In this article, Tanya Kothari, Agriculture Research Manager at Shell Foundation reflects on the benefits of off-grid cold chain solutions drawing on insights and examples from Shell Foundation’s portfolio companies.

Addressing post-harvest loss (PHL) with cold chain technology unlocks significant economic gain for smallholder farmers across emerging markets, improves product quality and makes a meaningful impact on climate adaptation and mitigation, writes Tanya Kothari, Agriculture Research Manager at Shell Foundation (SF).

- $4 billion of grains is loss annually in Sub-Saharan Africa, greater than the total value of food-aid the region received in the last decade.¹ Reducing this loss would create direct economic gains for rural, agricultural households.

- If global PHL was a country, it would be the world’s 3rd largest emitter as it leads to 4.4 Gigatons of annual GHG emissions globally.²

A key contributing factor to PHL is a lack of access to reliable cold storage and transportation across the value chain, especially close to the farm gate. Access increases the commercial viability of agriculture by increasing volumes and value of fresh produce, reducing logistical costs, improving smallholders’ bargaining position, and enabling producers and distributors to tap into high value export markets. These impacts are not limited to perishable fruits and vegetables, but also for a range of other commodities, including milk, pulses, and fish.

At Shell Foundation, a UK-based charity that supports access to energy solutions alleviating poverty across Africa and Asia, we help confirm the impact of access to reliable cold chain through working with innovative technologies and business models across multiple value chains and geographies including InspiraFarms, KeepITCool and Inficold in Kenya and India. Our work is in partnership with the UK’s Foreign, Commonwealth & Development Office (FCDO) through the CASEE³ programme.

The amount of post-harvest loss prevented by cold chain is massive. In India, for example, Inficold’s solar-thermal cold storage led to reduction of pulse losses from 15% to 2% for a customer and Inficold’s bulk milk cooler ended the earlier wastage of ~9% milk for their dairy customer. But we also saw impacts beyond PHL:

1. Improvement in product quality

Cold chain improves quality and margins, particularly critical in highly perishable meat and dairy sectors. KeepITCool’s refrigerated trucks and retailer cooler boxes prevent fish from deteriorating during transportation and storage in Kenya, enabling retailers to access higher quality fish supplies, which allows them to charge a premium.

For milk, off-grid chillers supply not just cooling but speedy cooling, which is critical to ensure higher quality. The Inficold solar instant milk chiller has the capacity to instantly cool 3,000L of milk from 35°C to 10°C. Faster cooling reduces the chances of milk spoilage, improves milk quality, reduces energy demand, reduces its carbon footprint, and increases profits.

Versatile cold chain technology also enables higher food safety. For example, without cold storage infrastructure, calcium carbide, a banned carcinogen, is often used to ripen bananas and increase margins. Freeze drying of pulses is another example of a cold chain solution eliminating chemicals, by preventing the need for pesticides and rodent killers.

2. Increased Revenue for farmers, agribusinesses, and retailers

Across value chains, cold chain leads to higher incomes for farmers and agribusinesses.

KeepITCool enabled fisherfolk to achieve better payment terms by increasing market linkages and stabilising offtake prices. They extend cold storage all the way to the retailer, ensuring fish quality does not deteriorate during transport. Retailers sourcing from KeepITCool increased their maximum sale price from USD $3.8 to USD $7 per kg of fish. As a result, fisherfolk cooperatives can obtain higher prices for their products. This also enables KeepITCool to offer cash payments, when most local off-takers insist on credit terms, and to set up an offtake agreement. This guarantees the fisherfolk prompt payment for their produce and ensures stability of demand, preventing economic losses occasioned by disposal of fish at throw-away prices during the high catch season.

Other examples include an Indian dairy that installed Inficold’s bulk milk chiller and increased their monthly revenues by 330% within 5 months due to higher milk quality, reduction in wastage and the ability to balance demand and supply; an all-women farmer cooperative of 268 pulse farmers, where an extra income of around 10–15% was realised by the farmers using one of Inficold’s cold storage facilities; and Inficold’s banana ripening facility doubling the annual income of 10 farmer families in the Nayanagar village in Uttar Pradesh, India to USD $9333.

3. Cost reductions

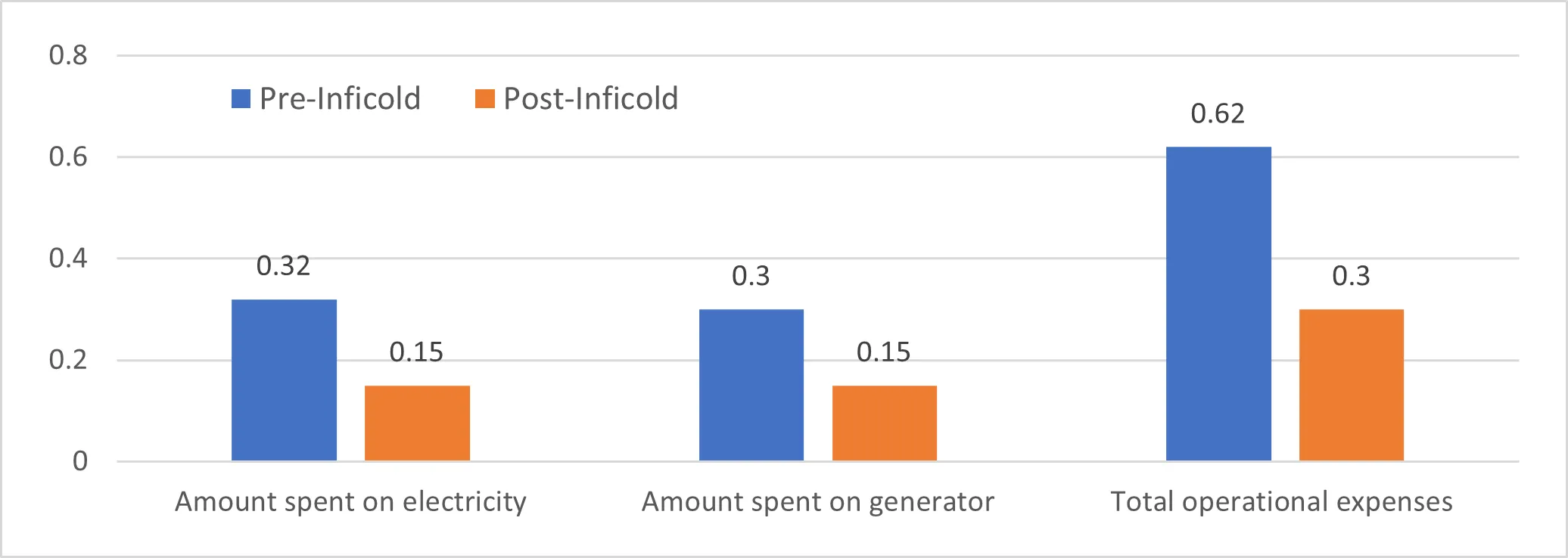

Solar-powered cold storage leads to reduction in operational expenditure of diesel powered gensets. The operational costs of an Inficold dairy customer reduced by 50% following the installation of the solar instant milk chiller in 2020 (Figures 1 and 2).

4. Reduction of CO₂e emissions

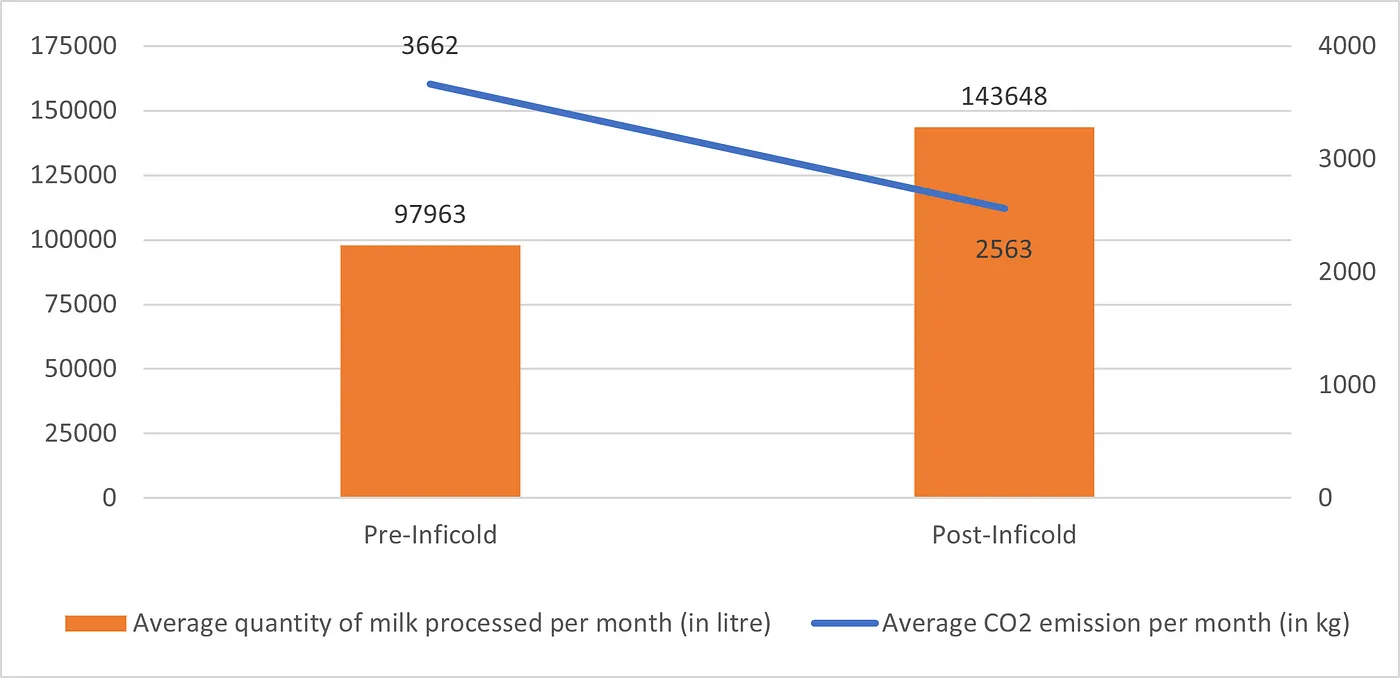

The climate mitigation impact of solar cold storage is due to reduction in post-harvest loss as well as replacement of diesel gensets which are used for powering cold storage in the absence of reliable grid electricity. Inficold’s bulk milk cooler results in annual savings of greenhouse gas equivalent of 23.6 MT CO₂⁴ Similarly, using their Instant Milk Chiller, their customer reduced their carbon emissions by around 30% (Figure 3).

5. Climate Adaptation Impact

The impact of cold storage is more acute in a warmer climate as the same amount of deterioration can occur in one hour at 25°C as in one week at 1°C, for many horticultural commodities.⁵ The rate of food spoilage increases nonlinearly with higher temperatures, so the link between investments in cold storage and climate adaptation is clear, as outlined in SF’s recent report ‘Catalysing Climate Finance for Low-Carbon Agriculture Enterprises’.

How can we scale off-grid cold chain?

In a Delphi Analysis⁶ conducted by InspiraFarms with 150 stakeholders, there was a consensus (Figure 4) that the key challenge to the adoption of cold storge in rural agricultural value chains was access to finance (96%).

Small scale growers do not have access to finance to invest in their own infrastructure. The median monthly income among smallholders in Kenya is USD $28, which makes upfront investment in a high-cost asset challenging. In India, existing credit facilities do not allow the cooling equipment to be considered as collateral, which is common in sectors like the automotive sector.

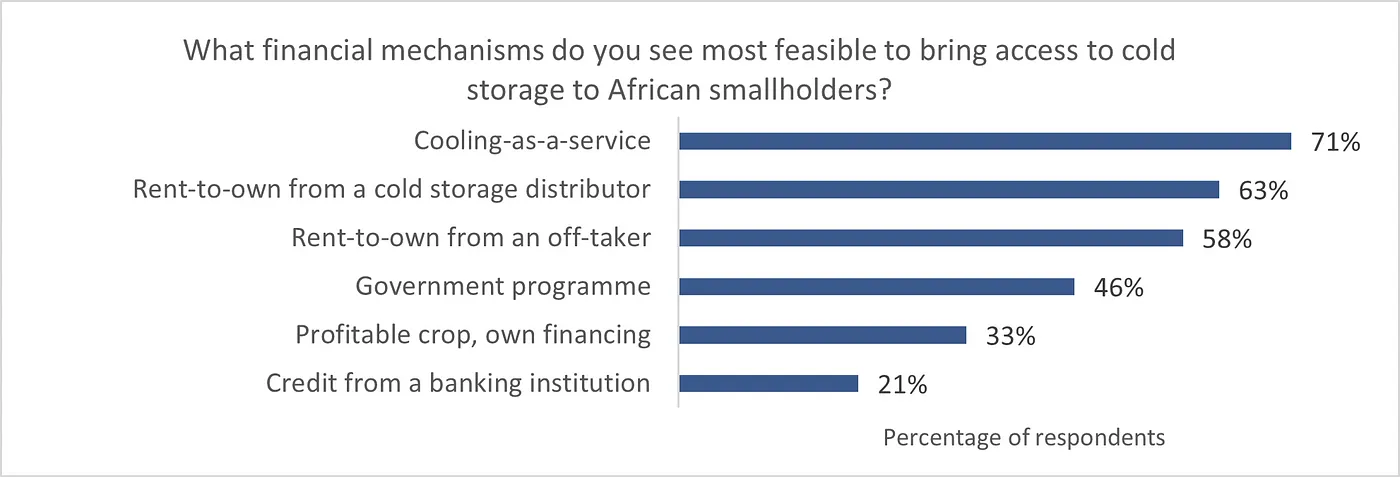

The stakeholders could not reach a consensus on a possible financial mechanism to solve this challenge (Figure 5). However, 71% of respondents considered Cooling-as-a-Service (CaaS) as the most workable way to provide small scale growers with access to the technology. CaaS is a business model in which a service provider such as a cooperative or entrepreneur allows farmers to store fresh produce in their cold storage unit for a fee, based on their needs and payment ability.

The cold storage sector (especially first-mile) and cold chain applications are nascent yet growing, with affordability and accessibility being the key challenges to overcome. There is no one-size-fits-all solution and innovative business models need to be tested and scaled. Stakeholders can support the sector and expand the reach of cooling solutions to first mile farmers:

1. Unlock capital for distributed cold storage solutions: Governments and development partners can ease private sector investments by supplying capacity building and financial instruments such as first loss for local financial institutions, which could increase local currency lending.

2. Invest in local relationships: InspiraFarms, Inficold and KeepITCool have built relationships with multiple retailers, agribusinesses, dairy, fishing and farming cooperatives, governments, and investors with experience across geographies, allowing for a broad analysis of the factors affecting commercial viability of their operations and of the smallholders they engage.

3. Develop multi-stakeholder partnerships: Effective partnerships between local agribusinesses, producer organizations, solution providers, governments, and financiers, with the needs of the local stakeholders at the forefront, are fundamental to develop the technology and the knowledge base, communicate impact, and catalyze investment.

4. Conduct further research and piloting: There is a need to explore various business models to decide how return-on-investment and added value can be created for all value-chain actors.

END NOTES

¹ 3 Ways to Tackle Food Loss and Waste in Africa

² Climate change and post harvest loss: APHLIS blog post

³ Catalysing Agriculture by Scaling Energy Ecosystems (CASEE) is a £30m, seven-year partnership between Shell Foundation (SF) and the UK Government launched in 2019 to accelerate access to energy-enabled solutions for smallholder farmers and agricultural SMEs (small and medium sized enterprises) in sub-Saharan Africa and South Asia.

⁵ Winkworth-Smith, C.G., T.J. Foster, and W. Morgan. “The Impact of Reducing Food Loss in the Global Food Chain.” University of Nottingham, March 201

⁶ A Delphi analysis approach involves administering several rounds of questionnaires to a panel of experts. After each round, respondents are provided with an anonymised summary of the responses provided by the panel and encouraged to revise their earlier answers, in light of the other experts’ replies. This process aims to lead the group to converge towards the “correct” answer. A consensus is commonly considered when 75% of stakeholders reach an agreement but can be strengthened throughout the process. InspiraFarms performed a Delphi Analysis initially targeting 150 stakeholders from the African fresh produce supply chain, within four rounds of questions. Stakeholders surveyed included growers, agribusiness owners, exporters, freight companies, NGOs, consultants, and academic research institutions.

This article draws on insights and experiences from SF portfolio companies:

InspiraFarms: InspiraFarms designs, develops and supplies modular and energy-efficient on-farm and close-to-farm cold rooms and packhouses for the horticultural sector in emerging markets, with a focus in African countries. Read their recent learning report here.

KeepITCool: Keep IT Cool provides affordable, reliable and efficient cold chain solutions to support the East African fishing and white meat sector. Read their recent learning report here.

Inficold: Inficold designs and manufactures cold storage room, milk coolers and air conditioners with grid resilient and off-grid solar integration options. Read Inficold’s upcoming reports on SF website here.

ABOUT THE AUTHOR

Tanya Kothari leads research, evidence generation and advocacy for Shell Foundation’s energy and agriculture portfolio. Prior to this, she managed SF’s gender inclusion programme in India, while supporting the development of the portfolio across energy and agriculture sectors.